Connecting batteries in parallel for maximum capacity is a strategic financial decision for off-grid and mobile energy systems, not just a wiring task. Optimizing a parallel battery connection directly impacts the system’s Total Cost of Ownership (TCO) and long-term reliability. For example, using high-cycle Lithium Iron Phosphate (LFP) cells with an active-balancing BMS can cut 10-year energy bank costs by roughly a third compared to typical AGM banks. Conversely, a naive parallel bank with imbalanced cells or no proper management will drive up maintenance costs and shorten its lifespan, undermining the return on investment.

Strategic Component Selection – The Foundation of TCO

The best long-term value in a parallel battery system comes from selecting LFP batteries and a BMS with full active balancing. High-cycle LFP cells deliver far more usable energy and longevity per dollar than lead-acid, which dramatically reduces replacements and maintenance. In practice, pairing LFP chemistry with an active-balancing Battery Management System (BMS) yields the lowest total cost of ownership over more than ten years, despite a moderately higher upfront cost. Such a configuration maximizes usable capacity and ensures each cell is protected, a key factor in minimizing downtime and extending ROI.

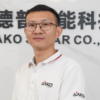

Battery Chemistry Comparison

LFP batteries outperform AGM lead-acid in every metric that matters for TCO. The table below contrasts data from commercial packs: LFP has a higher upfront cost per kilowatt-hour but supports thousands of cycles at a deep Depth of Discharge (DoD), delivering many times more lifetime energy throughput. Even though LFP packs cost more per kilowatt-hour initially, their three to four times longer cycle life results in a far lower 10-year TCO on a delivered-energy basis.

| Battery Type | Upfront Cost per kWh | Cycle Life @ 80% DoD | Lifetime Energy Throughput (kWh) | Est. 10-Year TCO |

|---|---|---|---|---|

| LiFePO₄ (LFP) | ~$350 | ~3,000 | ~2,400 | ~$350–$400 |

| AGM Lead–Acid | ~$200 | ~500 | ~250 | ~$600 |

Prices reflect 2025 market estimates: lead-acid modules run roughly $150–$250 per kWh, whereas new LFP packs are about $100–$130 per kWh at the cell level (all-in pack costs are higher, as shown). In practice, this means one kilowatt-hour of LFP capacity can cycle approximately 3,000 times, delivering about 2,400 kWh over its lifetime.

In contrast, an AGM battery provides around 500 cycles, delivering approximately 250 kWh. Thus, for a given energy demand over 10 years, an LFP bank requires far fewer replacements. The illustrative 10-year TCO above assumes scaled replacements: an AGM bank will likely need two full swaps, roughly tripling the initial cost, to last a decade, whereas a quality LFP string often lasts the full term unchanged.

Data-driven insight: In a real-world solar and storage case, replacing AGM with LFP batteries increased the cycle life from 800 to over 4,000 cycles and reduced the 10-year system cost from $42,000 to $28,500. This nearly 32% cost reduction occurred despite a higher LFP capital cost; the net gain came from the vastly greater number of usable cycles and total energy delivered.

BMS Selection Criteria

Effective parallel battery systems demand an intelligent Battery Management System (BMS). Key features to evaluate in a multi-string BMS include:

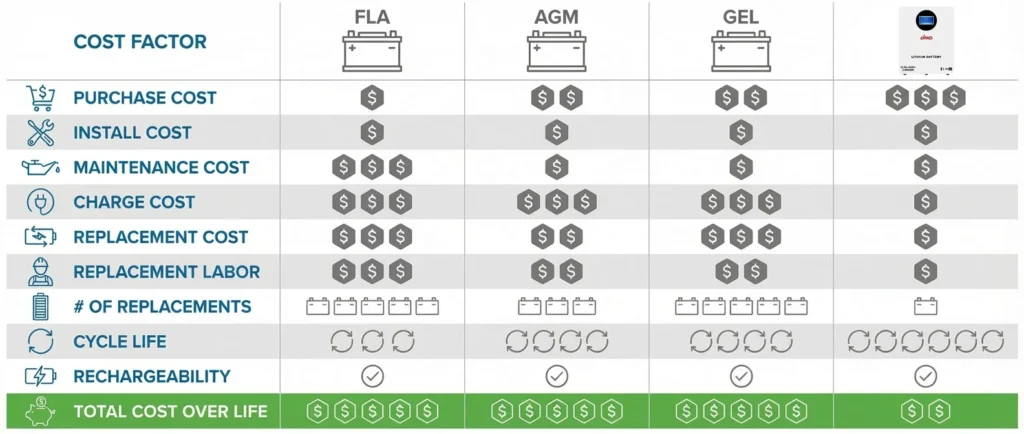

- Active Cell Balancing: Ensures all cells, even across parallel strings, share current uniformly. Without active balancing, one cell can drift to a higher or lower state-of-charge, causing repeated overcharge or overdischarge events. Active balancing capability, via charge shuttling or dissipative methods, equalizes cells during charge and discharge cycles, maximizing usable capacity.

- Individual Cell-Voltage Monitoring: The BMS must measure every cell’s voltage independently. This allows for the detection of outlier cells in a parallel bank; even small voltage deviations can signal an imbalance or a failing cell. Early alerts enable corrective action before cascade failures occur.

- State of Health (SoH) Algorithms: Advanced BMS logic that estimates battery health by tracking metrics like capacity fade and internal resistance rise helps forecast the end-of-life before failure. SoH estimates guide maintenance scheduling and replacement planning, maximizing uptime and asset value by proactively maintaining only what is necessary.

- Robust Communication: Modern parallel systems require high-bandwidth, industrial networking.

- Robust Communication (e.g., CAN bus): Modern parallel systems require high-bandwidth, industrial networking. A CAN-bus or similar interface facilitates real-time telemetry and integration with system controllers. This is critical for remote monitoring and centralized control of large banks and allows BMS data to directly influence system operation, for example, by derating output on low states.

- Redundancy and Fail-Safe Design: In multi-string setups, ideal BMS solutions provide redundancy through multiple monitoring and control units so that a single point of failure cannot compromise the entire bank. Look for BMS units designed specifically for parallel LFP systems, as these include protections against uncontrolled equalization currents between parallel modules.

Each of these BMS capabilities directly ties to System Reliability: a high-quality parallel-architecture BMS prevents cell drift and uneven aging that would otherwise degrade reliability and increase long-term TCO. By actively managing cell balancing and health, the BMS turns raw battery strings into a provably safe, reliable bank.

Long-Term Operations & Reliability Management

Guaranteed reliability and safety come from proactive monitoring and solid hardware protections. Beyond selecting durable components, you must continuously safeguard the bank during operation. Long-term system reliability is achieved through real-time monitoring of battery condition and robust electrical safety hardware – these are non-negotiable for any mission-critical parallel battery design.

Proactive Monitoring Strategy

A proactive monitoring strategy continuously checks each cell’s condition to catch issues early. Specifically, tracking cell voltage deviations and internal resistance trends can predict failures before they happen. Even slight voltage mismatches among parallel cells hint at imbalance; if left unchecked, one cell can suffer overstress while others hog current. Similarly, a cell’s rising internal resistance is a red flag for degradation. Studies show that as a cell ages, its internal resistance steadily increases, causing heat, energy loss, and eventual sudden failure. Regularly logging these parameters lets aged or failing cells be identified long before they limit performance.

For example:

- A BMS that logs per-cell voltages can flag if one cell in a string is chronically high or low compared to the group. This triggers maintenance before capacity loss escalates.

- Tracking each cell’s DCIR (direct current internal resistance) over time reveals which cells are deteriorating. An upward trend in internal resistance correlates with capacity fade. By analyzing these trends, the BMS or operator can schedule rebalancing or replacement proactively.

- Comparing equalizing currents, if active balancing is available, also provides insight: excessive balancing current over time means the cells are diverging in capacity and need attention.

In short, measuring every cell’s voltage and resistance allows a predictive health model. This insight translates directly to system reliability: failures can be prevented rather than reacted to. As one review notes, internal resistance growth and voltage shifts are key indicators of battery health and enable the prediction of remaining useful life.

A well-instrumented BMS effectively becomes a “preventative maintenance” tool, locking in ROI by avoiding surprise downtime and catastrophic replacements.

Essential Safety Hardware

No parallel bank is complete without hardwired safety components. These devices are a last line of defense against electrical faults.

- Main Fuse (Bank-Level Protection): Install a high-current fuse or equivalent on the positive output of the entire bank. This main fuse prevents runaway short-circuit currents if the pack is accidentally shorted. Sizing: The fuse rating should exceed the normal maximum current (e.g., 125% of peak load) but be low enough to blow under fault conditions. For instance, if your bank can supply 500 A continuous, a 600–650 A fuse will carry normal current yet interrupt a dead-short. This protects cells against catastrophic failure and fire risk.

- Individual String Breakers: Each parallel string should have its own breaker or fuse on the positive lead. If one string develops a fault, such as a failing cell or internal short, its breaker isolates just that string instead of the entire bank. This allows continued operation, minus one string’s capacity, while the faulted string is serviced. These breakers also provide a safe means to disconnect a string for maintenance or cell replacement.

- Master Disconnect Switch: A manually operated disconnect switch rated for the bank’s voltage and current provides an emergency cut-off between the batteries and the rest of the system. In an emergency, such as a fire or thermal runaway detection, this switch lets the operator instantly de-energize the bank. Many integrators use rotary or high-amp knife switches with clear “ON/OFF” markings as the battery master cutoff. This device should be sited within easy reach, labeled, and rated for the full pack voltage and fault current.

Each safety component must be rated for worst-case conditions; use materials specified for DC service at your system voltage. By combining monitoring with these fail-safes, you ensure that no single fault can cause an uncontained failure of the parallel array. This layering of protections—active monitoring plus passive safety hardware—is what ultimately guarantees system safety and reliability over the battery bank’s lifespan.

Conclusion & Decision Framework

In summary, a reliable high-capacity battery bank is built on strategic upfront choices and disciplined operation. Selecting LFP cells with an active-balancing BMS maximizes usable energy and minimizes replacements, cutting TCO significantly. Likewise, instituting rigorous monitoring of cell voltages and state of health, and installing proper fuses and switches ensures longevity and safety. Every decision—from chemistry to BMS features to safety hardware—should be evaluated in terms of its impact on TCO and reliability goals.

5-Point Strategic Checklist for Parallel Battery Systems:

- Battery Chemistry Choice: Are you using LFP or another high-cycle chemistry? High cycle count (>2000 cycles) means lower life-cycle cost.

- BMS Feature Set: Does your BMS include active balancing, per-cell monitoring, State of Health (SoH) estimation, and CAN communications? These capabilities are essential for parallel strings.

- Cell Matching & Initial Balancing: Have cells been matched and balanced before assembly? Proper initial balancing prevents early skew.

- Monitoring & Maintenance Plan: Are you logging cell metrics like voltage, temperature, and internal resistance, and reviewing SoH trends regularly? Predictive insight is critical.

- Safety Protections: Are appropriate fuses, breakers, and disconnects sized and installed? Verify each is rated above normal current but will interrupt faults.

By rigorously answering these checkpoints, system integrators can ensure a parallel battery design that meets ROI targets. In practice, this means investing wisely in quality cells and management electronics up front, then executing vigilant operational procedures.

That combination—strategic design plus proactive management—is the key to achieving low Total Cost of Ownership (TCO) and rock-solid reliability in any high-capacity parallel battery installation.